The inappropriate and limited management of organic waste causes it to be disposed of in streets or landfills, negatively impacting the various ecosystems due to leachate, the appearance of vectors, and the emission of greenhouse gases. Taking advantage of this waste under the concept of circular economy is a viable alternative, one way to do it is by transforming it into compost for agricultural activity. This research seeks to propose a new use of organic waste with favorable characteristics to obtain biomaterials. The elaboration of bioplastic from pectin extracted from the peels of citrus fruits and apples was tested. Through aqueous extraction, the pectin was obtained to later transform it into a bioplastic with the addition of citric acid, glycerol, carboxymethylcellulose, and water. They were experimented with using three doses, being the best dose to produce the bioplastic with the best properties when using 1 % citric acid, 7 % glycerol, 0.39 % carboxymethylcellulose and 2 % pectin, a bioplastic that presented elongation and tensile values of 7.3575. N/ cm2 and 62.22 %, percentage of water absorption of 94.26 %, 100 % biodegradability (in the soil) in 21 days, as well as 100 % degradation in water in 14 days and 28.39 % degradation in the open air in 28 days. Obtaining these biomaterials is a way to take advantage of citrus waste and other fruits with environmental sustainability advantages and within the concept of circular economy, which would avoid the use of plastics based on polluting chemical products.

1. Introduction

Population growth has had a considerable increase in the last decade, causing a high demand for fruits and vegetables, which in turn has generated an increase in organic waste (Magama, Chiyanzu and Mulopo, 2022). Of the 1,300 million tons of food that are wasted in the world during its production and commercialization (Selva, Adithya and VishalI, 2022), 20 % is valued and 50 % becomes organic waste (Wan, et al, 2022).

Organic waste, for the most part, usually presents inappropriate management, or it is very limited, so it ends up being discarded in streets and landfills, reaching various ecosystems (Lee, et al, 2022). This is how these residues generate air pollution, unpleasant odors, contamination of soil and bodies of water, degradation of landscapes, and reproduction of insects and rodents (Babu, Prieto and Rene, 2021). Therefore, consider the application of the circular economy model through valuation approaches with the objective that it is not only reducing the generation of food waste (Papargyropoulou, et al, 2014). and investigating alternatives for eco-friendly and eco-efficient recovery processes (Fazzino, 2021), is of the utmost importance. The use of organic waste to obtain products has been investigated in recent years, such as obtaining bioplastic from Manihot esculenta (cassava) and Ficus benjamina (Olivares, et al. 2021), obtaining paper from Ananas commusus (Velásquez, et al., 2021), elaboration of kitchenware from Carya illinoinensis (Campos et al., 2021), roofs from pile crown residues and sugarcane bagasse (Morales, et al., 2022), elaboration of sorbets from Mangnífera indica and Vitis vinifera (Gallardo, et al., 2022), among others.

This scientific document reports the evaluation of the physical-mechanical properties and biodegradability of a biomaterial from pectin, which is composed of up to 70% galacturonic acid in the plant and is found in various citrus fruits providing mechanical resistance to the cell wall, proving to be an element with potential use for the production of bioplastics (Gurram et al., 2018). In addition, for (Ministerio del Ambiente, 2022) in the last year the Ate district processed 570.85 tons of organic waste (such as citrus peels, apples, and others) in its recovery plant, evidencing the ability to process the biomaterial if the scale is increased.

2. Materials and methods

2.1 Raw material

Citrus and apple peels were collected from the Ceres market, in the district of Ate, for 7 days, obtaining a total of 14 kg and 9.90 kg of each type; then they were subjected to a pre-treatment before extracting the pectin, which consisted of performing two items of washing with shaking at 115 rpm for 20 min at 35 °C, cutting, drying at 40 °C for 16 hours and grinding.

2.2. Pectin extraction

This process was carried out using the aqueous extraction method (Passandide et al. 2017). Distilled water was added to the biomass obtained from citrus and apple peels in a 40:1 ratio and was subjected to a stirring process at 90 ºC for 180 min (Figure 1). Following the filtration process, the aqueous part was separated. To the solution obtained, alcohol was added in a ratio of 1.5:1 to precipitate the pectin. It was then centrifuged to separate the pectin from the alcohol. To obtain dry pectin, it was baked for 12 hours at 50 ºC. The dry pectin was characterized by determining its production yield, ash content, and moisture content by gravimetric method.

2.3 Bioplastic production

With citrus peel and apple pectin in a 1:1 ratio, 3 bioplastic samples were made with 3 replicates for each sample. The method used was the casting method (Bátori, 2017) under constant temperature conditions (95 ºC) and pH of acidified distilled water (3.5). The procedure began with the change of the pH of the distilled water to 3.5 by adding 2N HCL, followed by stirring at 250 rmp and 90 ºC for 40 min, adding citric acid, glycerol, carboxymethylcellulose and pectin in different doses (See Table 1). This homogenized mixture results in bioplastic. Example for bioplastic BP2, 1g of citric acid + 7g of glycerol + 0.39g of carboxymethylcellulose + 100 ml of water + 2 g of pectin were used, to obtain 100 g of bioplastic + water vapor. The bioplastic was put in Petri dishes and dried (see Figure 2).

Table 1: Amount of pectin and additives for bioplastic samples

| Bioplastic Sample | Citric Acid (g) | Glycerol (ml) | Carboxymethylcellulose (g) | Distilled Water (ml) | Pectin (g) |

|---|---|---|---|---|---|

| BP1 | |||||

| BP1-M1 | 6 | 11 | 0.39 | 75 | 8 |

| BP1-M2 | 6 | 11 | 0.39 | 75 | 8 |

| BP1-M3 | 6 | 11 | 0.39 | 75 | 8 |

| BP2 | |||||

| BP2-M4 | 1 | 7 | 0.39 | 100 | 2 |

| BP2-M5 | 1 | 7 | 0.39 | 100 | 2 |

| BP2-M6 | 1 | 7 | 0.39 | 100 | 2 |

| BP3 | |||||

| BP3-M7 | 3 | 2 | 0.39 | 100 | 25 |

| BP3-M8 | 3 | 2 | 0.39 | 100 | 25 |

| BP3-M9 | 3 | 2 | 0.39 | 100 | 25 |

BP1: Bioplastic 1; BP2: Bioplastic 2; BP3: Bioplastic 3; M1: Sample 1; …M9: Sample 9.

2.3 Characterization of the bioplastic

Finally, the bioplastic was characterized, evaluating the biodegradation (See figure 3) in soil, aqueous, and open air. Regarding the soil environment, it was collected from a natural area, screened at 2 mm to eliminate any impurity (vegetable or inert matter), with a water retention capacity between 40% and 60%, pH between 6-8 and organic matter content with a C

ratio of 40:1 (ISO 17556 method). For the aqueous medium and the outdoors, the mass loss method was applied. The tensile and elongation test of the material was also carried out, for which bioplastic strips 15 cm long and 2.50 cm wide were cut, various weights were applied, and time was measured.

The water absorption capacity was evaluated, following the procedure based on the ASTM D570-98 standard (immersion in distilled water), which consists of subjecting the samples in beakers with distilled water to a temperature of 21.5 ºC simultaneously, during intervals of 1, 3, 5, 10, 15, 20, 25, 30, and 60 minutes. Afterward, any water on the surface was removed and the samples were weighed.

Figure 3: Biodegradation process in soil

3. Results and Discussion

3.1 Traction and elongation of the bioplastic

The values obtained for traction force show that sample 1 supported a maximum force of 2.4525 N/cm² in an average time of 7.3 s; sample 2 reached its breaking point when 7.3575 N/cm² was applied in an average time of 20.35 s, and sample 3 tolerated a maximum force of 4.9050 N/cm² in 19.37 s. See Table 2.

The percentage of elongation obtained from the samples has a minimum value of 60% from sample 2 (BP2-M5 / BP2-M6), and a maximum value of 106.67 % from sample 1 repetition 1 (BP1-M1) and sample 3 (BP1-M9) (see Table 2). The difference between the tensile force and elongation values of the 3 samples is caused by the amount of glycerol added in each sample, as glycerol allows for an increase in elongation but decreases its tensile force. As mentioned by Giosafatto et al (2014), the elongation and traction values are due to the amount of glycerol used in the production of bioplastic since it causes the structure of the material to become flexible. Gustafsson et al (2019), also mention that if the elongation values increase, the tensile strength decreases.

Table 2: Values obtained from the tensile test

| Bioplastic | Repetitions | Elongation | Tractive Force (N/cm²) | Time (s) | Li (cm) | Lf (cm) | E (%) |

|---|---|---|---|---|---|---|---|

| BP1 | |||||||

| BP1-M1 | 15 | 31 | 106.67 | 2.4525 | 7.3 | ||

| BP1-M2 | 15 | 30 | 100.00 | 2.4525 | |||

| BP1-M3 | 15 | 28 | 86.67 | 2.4525 | |||

| BP2 | |||||||

| BP2-M4 | 15 | 25 | 66.67 | 7.3575 | 20.35 | ||

| BP2-M5 | 15 | 24 | 60.00 | 7.3575 | |||

| BP2-M6 | 15 | 24 | 60.00 | 7.3575 | |||

| BP3 | |||||||

| BP3-M7 | 15 | 31 | 80.00 | 4.9050 | 19.37 | ||

| BP3-M8 | 15 | 30 | 93.33 | 4.9050 | |||

| BP3-M9 | 15 | 28 | 106.67 | 4.9050 |

3.2 Bioplastic water absorption

The final values obtained in water absorption indicate that sample 3 has a value of 85.48%, sample 2 reaches a value of 94.26%, and sample 1 exceeds 100% (See Table 3). This is due to the dose of glycerol applied in each sample since glycerol contains a hydrophilic part. Arrieta, Durango, and Arizal (2018) mention that a determining factor in the absorption capacity of water or aqueous solutions of a biomaterial is the absence or presence of the plasticizer. This is because, when in contact with the pectin, it causes holes in its structure and collaborates with the wetting of the bioplastic, that is, the structure becomes porous and capable of absorbing humidity from the environment. In their experimentation, they obtained results with great differences depending on the presence of glycerol (plasticizer). In samples without glycerol, the values obtained vary between 9.14% and 13.99%, and in samples with glycerol (dose between 3g and 5g) between 43.29% and 48.66%, attributing said results to the presence of the plasticizer, which is verified in this investigation.

Table 3: Percentage of absorption of bioplastic samples

| Bioplastic | Wi (g) | Wf (g) | Absorption percentage (%) |

|---|---|---|---|

| BP1 | 3.78 | 9.39 | 148.41 |

| BP2 | 3.31 | 6.43 | 94.26 |

| BP3 | 7.85 | 14.56 | 85.48 |

3.3 Biodegradability and bioplastic degradation

Biodegradation in Soil

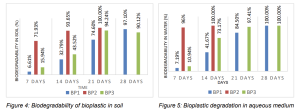

The results obtained for the biodegradability at 28 days in a soil medium (pH 6-8 and C ratio of 40:1, organic matter 10%, humidity 30%, electrical conductivity 2.2 ds/m) for the samples were: BP1 presented an average of 97.10%, the BP3 sample an average of 90.12%, and the sample BP2 100%, being the sample with the highest percentage of biodegradability obtained between 14 and 21 days. These results are shown in Figure 4. Other investigations also obtained similar values, such as the one carried out by Günkaya and Banar (2016), who elaborated bioplastics achieving biodegradability values of 70% in 9 days, reaching 78.4% in 15 days, attributing it to the pH and organic matter present in the soil, since this allows and helps microorganisms to quickly produce enzymes to degrade biofilms. Espinoza et al., 2022 mention that soils that have organic matter in their composition can biodegrade more easily, even by larvae compared to those that do not contain it.

Biodegradation in aqueous medium

The results obtained for degradation in an aqueous medium present minimum values of the BP1 sample with a percentage of 7.19% and the BP3 sample with 10.94% after 7 days of testing, achieving complete degradability in 28 days. The BP2 sample obtains a maximum value of 96% in 7 days and completes its degradation in 14 days (see Figure 5), which happens due to the pectin content in its composition. Chinaglia, Tosin, and Degli-innocenti (2018) explain that pectin is a great source of carbon, which contributes to the growth of microorganisms that produce enzymes such as pectinase, which bind to pectin, initiating biodegradation. Additionally, in aerobic conditions, they are quickly converted into biomass and then into CO2. However, molecular biodegradability must also be considered, as biodegradation is affected by the size of the particles.

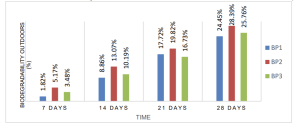

Degradation of bioplastic outdoors

The outdoor samples presented degradation values in a range of 1.82% in 7 days and 24.45% in 28 days in the BP1 sample; the BP2 sample in 7 days presents an average of 5.17% and 28.39% in 28 days; and the BP3 sample is in a range of 3.48% and 25.76% in 7 and 28 days, respectively (See Figure 6). As can be seen, the results obtained from the 3 samples do not present a considerable difference, however, they were not able to degrade completely due to the climate and environmental factors. Almirón et al. (2021) mention that bioplastics subjected to weather for 4 months obtain values ranging from 7% to 13%, which are determined by environmental conditions such as the climate and temperature of the area.

Figure 6: Degradation of the bioplastic in the open air

Statistical analysis of biodegradability results

First, the normality test was carried out for the percentages of biodegradability through the Shapiro-Wilk test, confirming the normality of the samples. Then, the relationship between biodegradability and the amount of pectin in each sample was analyzed through the ANOVA test (see Table 4), observing values less than 0.05 in the soil and water medium for 7 and 14 days, demonstrating significant differences in biodegradability. For 21 and 28 days, there is no significant difference, as at these times the percentage approaches 100% biodegradability. In the open air, the samples do not have significant differences. With these results, the test of homogeneity of variances (Levene’s statistic) was subsequently applied, finding similar results. Therefore, the hypothesis that the bioplastic obtained from citrus peel pectin and apple biodegrades with a percentage greater than 50% is accepted.

Table 4: ANOVA test for biodegradability

| Biodegradability | Day | 7 | 14 | 21 | 28 |

|---|---|---|---|---|---|

| % biodegradability in soil | F | 37.7 | 28.6 | 2.7 | .563 |

| Sig | .000 | .001 | .143 | .597 | |

| % biodegradability in water | F | 294.7 | 7.7 | 28.5 | – |

| Sig | .000 | .043 | .001 | – | |

| % biodegradability outdoors | F | 5.8 | 3.6 | .240 | .372 |

| Sig | .390 | .095 | .794 | .704 |

4. Conclusions

Citrus and apple peels could be used to manufacture biomaterials from the pectin they contain, as long as the tests and studies are expanded. The bioplastic obtained presents mechanical physical characteristics similar to synthetic bioplastics such as water absorption in a range of 85.48% to 148.41%, elongation of 60% and 106.67%, tensile strength of 2.425 N/cm² to 4.9525 N/cm², and in general complies with the regulated percentage of biodegradability, even reaching 94% to 100% in a period of 21 to 28 days. Therefore, the production of bioplastics is a way to eliminate and recycle waste after its useful life or the use of organic products, at the same time reducing the negative impacts on the environment.

Author

-

Victoria N. Jara Ramirez is a researcher at César Vallejo University specializing in chemical engineering. Her work focuses on sustainable waste management practices aimed at environmental conservation.